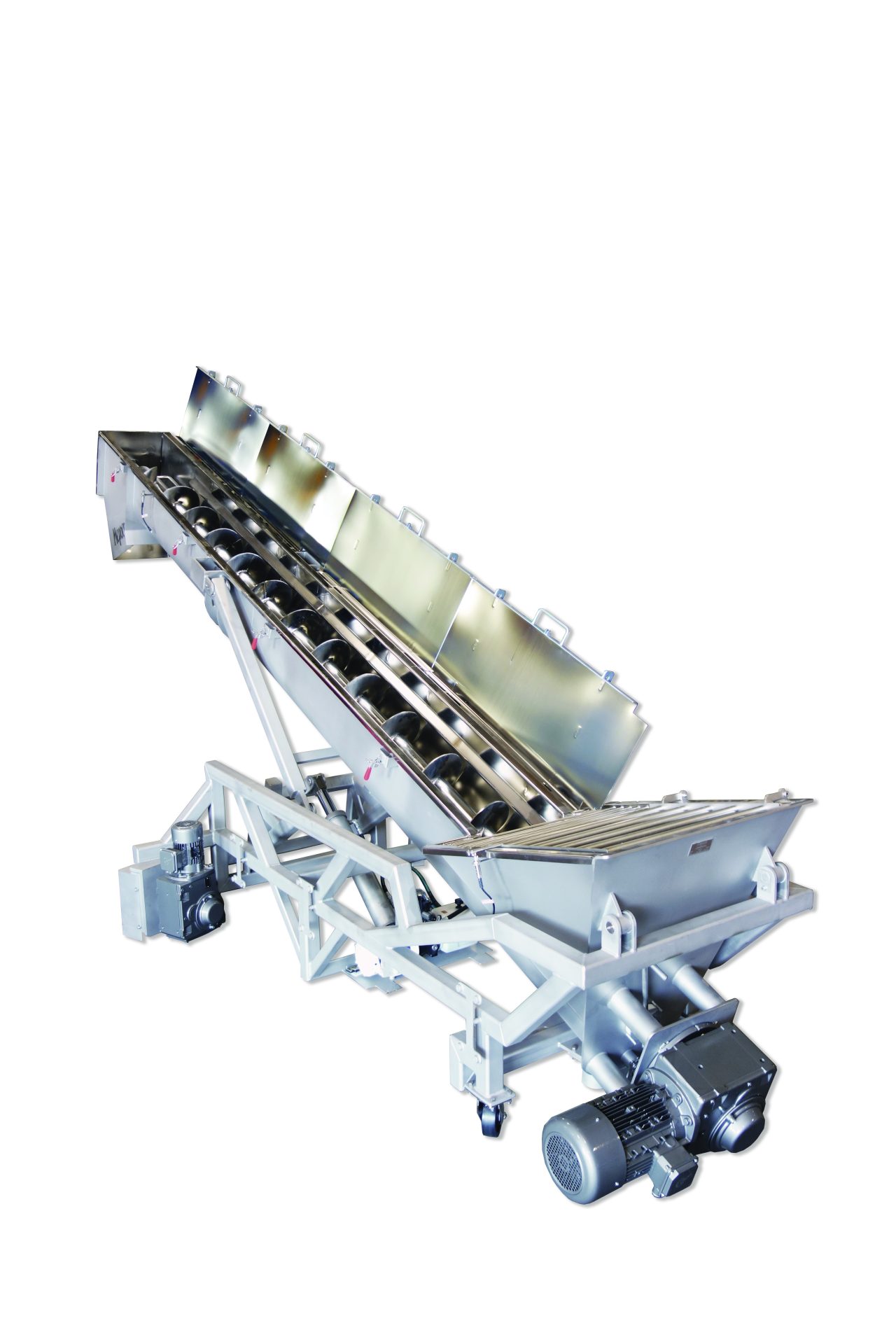

Incline

Screw Conveyors

Mepaco leverages our food industry experience to provide the best incline and contained screw conveyor solution for the application. This equipment is highly customized, with options that solve production goals.

Application Customization

- Pivoting screw, drop-down conveyor, or rail system design

- Variable pitch flights

- Manual or lift-assist safety grating

- Contoured, solid or domed grated covers

- Insulation and cladding

- Thermal screws

- Bead blast, pickle passivated or electropolished surfaces

- Gear box mounting styles: Flange mount, shaft mount with torque arm, or chain and sprocket

- CIP / Sprayballs

Design Features and Customization

- Quick release seal

- Coupled motor drive shaft

- Load cells

Application Expertise

- Co2 Conveyor – Screw incline conveyor design to meter product while reducing product temperature

- Screw Incline with CIP – Screw incline designed with CIP (clean-in-place) capability and a fixed base with elevated pivot track

- Thermal Screw – Inclining screw conveyor system with indirect heating of product through thermal screw technology

Related Posts

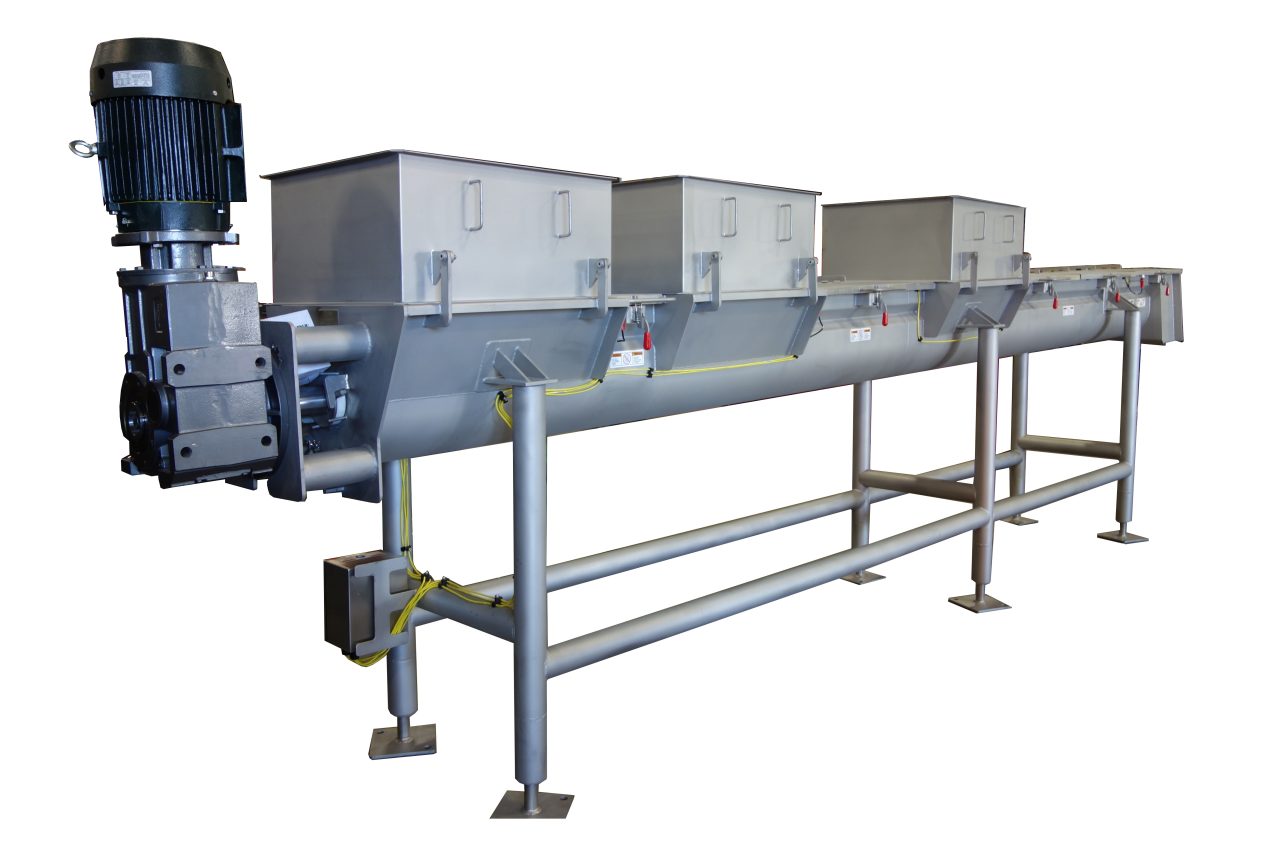

Metering

Screw Conveyors

Metering Screws are designed with bins that feed product into the conveying system. Designed as part of a system, these Metering Screws offer surge loading benefits to increase yields for your production goals.

- Hopper Designs: Clean Sweep, Cross Screw or Center Bottom Screw

- Variable pitch flights

- Manual or pneumatically controlled lift-assist safety grating

- Contoured, solid or domed grated covers

- Insulation and cladding

- Thermal screws

- Bead blast, pickle passivated or electropolished surfaces

- Gear box mounting styles: Flange mount, shaft mount with torque arm, or chain and sprocket

- Cut flighting for pre-breaking

- Heating or chilling jackets

- CIP / Spray balls

Design Features and Customization

- Quick release seal

- Coupled motor drive shaft

- Load cells

Configurations

- Clean-Sweep

- Cross Screw

- Dual Screw

Related Posts

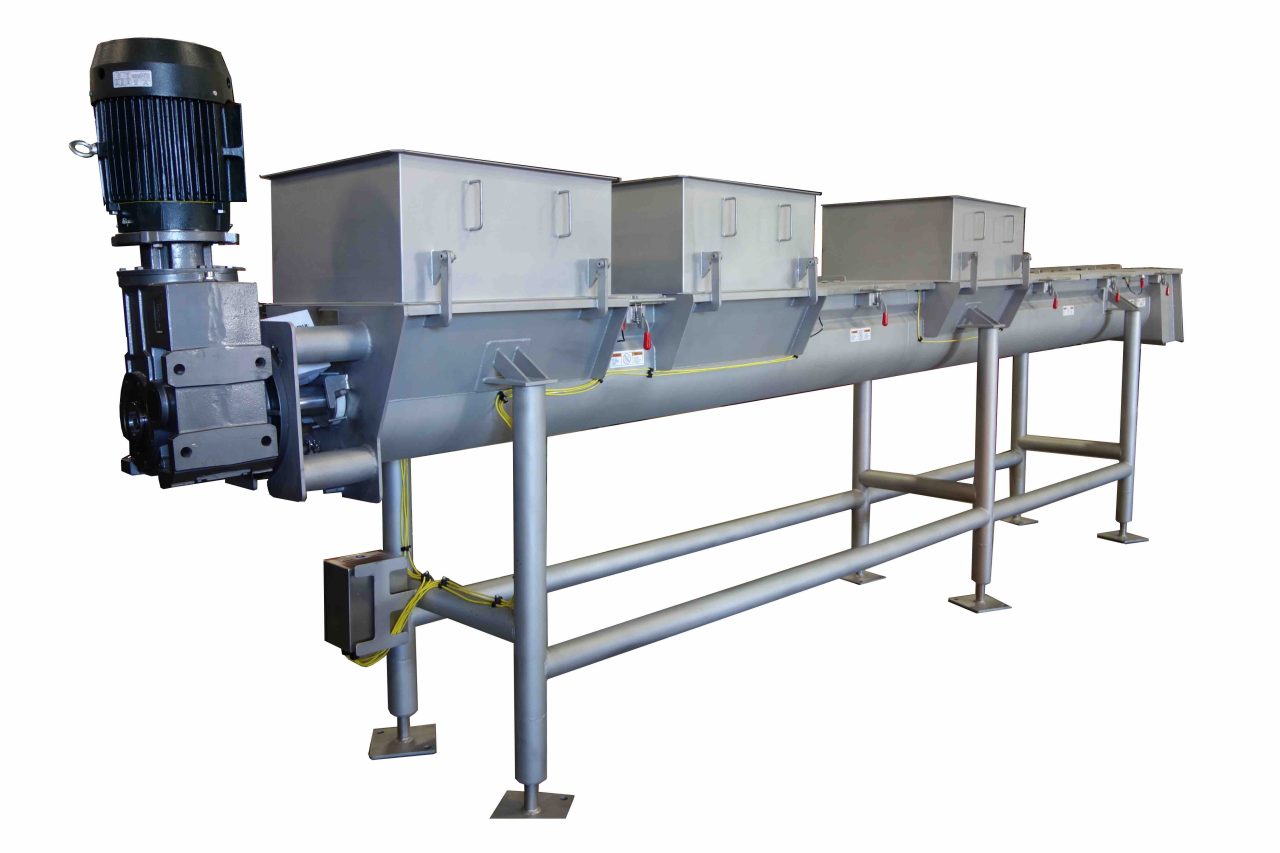

Transport

Screw Conveyors

Mepaco’s Transport Horizontal Screw Conveyors offer options and capacities to allow efficient and effective product handling. Screw conveyors are designed for full bulk product containment and aggressive sanitation.

Application Customization

- Pivoting screw, drop-down conveyor, or rail system design

- Variable pitch flights

- Manual or lift-assist safety grating

- Contoured, solid or domed grated covers

- Insulation and cladding

- Thermal screws

- Bead blast, pickle passivated or electropolished surfaces

- Gear box mounting styles: Flange mount, shaft mount with torque arm, or chain and sprocket

- CIP / Sprayballs

- Reversing horizontal screws

Design Features and Customization

- Quick release seal

- Coupled motor drive shaft

- Load cells

Extremely professional

We were extremely impressed with the amount and quality of work your crew did in a short time. Your crew did a fantastic job of repairs and were extremely professional. I know it was long hours and over the holiday, but you didn’t let up until it was done. It was a monumental task and you hit it out of the park from all aspects. We truly appreciate our partnership.

Michael,

Freshpet

FAQ – SCREW CONVEYORS

We offer No. 4, bead blast, passivated and electropolished finishes.

Bulk density, surge or instant throughput requirement, infer and discharge elevation

From 4″ to 20″ diameter

Mepaco has made hoppers from 100 lb. to 8000 lb. capacity.

Gravity fed, cone, or clean sweep hopper with separate agitator.

We offer fixed leg and portable supports with casters using tubular or angled construction.

We offer heating and cooling through jacketed or insulated options.

We offer full length safety grating, including hopper.

Flange mount or torque arm, chain and sprocket or discharge driven.

At the indeed or at the discharge.

Yes, we can design a reversing screw depending on the application.

Mepaco’s Clean Sweep Surge Loader offers a solution that mechanically clears food product between batches on surge loading applications.