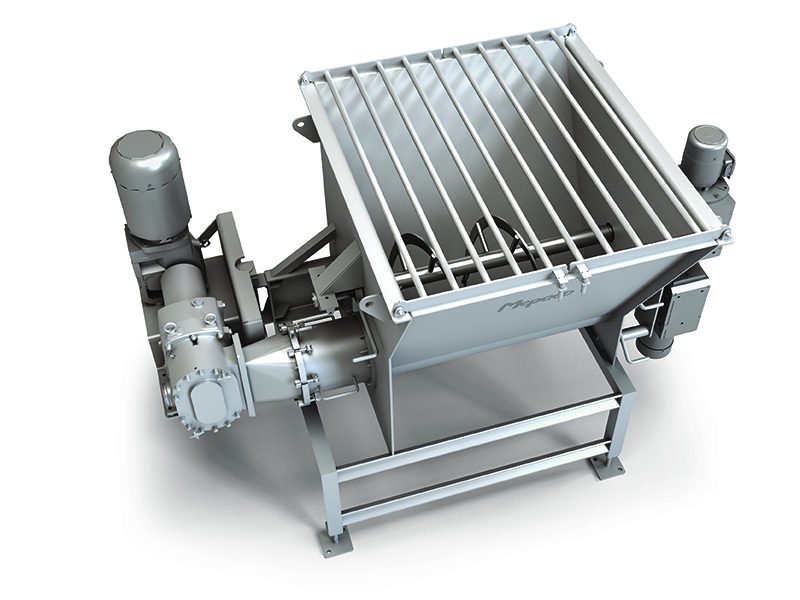

PosiFlo

Automatic Chub Feeder

The PosiFlo Automatic Chub Feeder can be integrated with a variety of chub packaging systems. By providing a consistent volume and continuous, efficient flow; the PosiFlo delivers even pressures with limited shear and temperature rise. From the first chub to the last, product weights and quality are maintained throughout the batch.

With optional pump sizes, the PosiFlo covers a broad range of production rates available to meet a variety of application challenges.

- Sanitary Design: Open Frame, stainless motors and pump

- Safety Grating: Eliminates the reach-in / fall-in hazard

- Finish: Electropolished food contact surfaces resist adhesion

- Pump Options: High and low capacity positive displacement

- Sanitary Seals: Quick release shaft seal for easy access

- Pump Mount: Swing away pump base for easy access

- Pump Transition: Inline orientation reduces smear and temperature rise

- Pressure Transducer: Provides automatic pressure sensing adjustment to ensure consistency

- Leveling Ribbon: Eliminates bridging and recycling of product

FAQ – POSIFLO AUTOMATIC CHUB FEEDER

What are the sizes of the PosiFlo?

Can the PosiFlo have heating or cooling jackets?

What auger sizes and configurations are available?

How do the auger(s) maintain the proper inlet pressure to the pump?

Can I put load cells on a PosiFlow?

What is the leveling ribbon used for?

My PosiFlow cavitates. How can I get a consistent flow?

Once the hopper is empty, how do you get the lines cleaned?