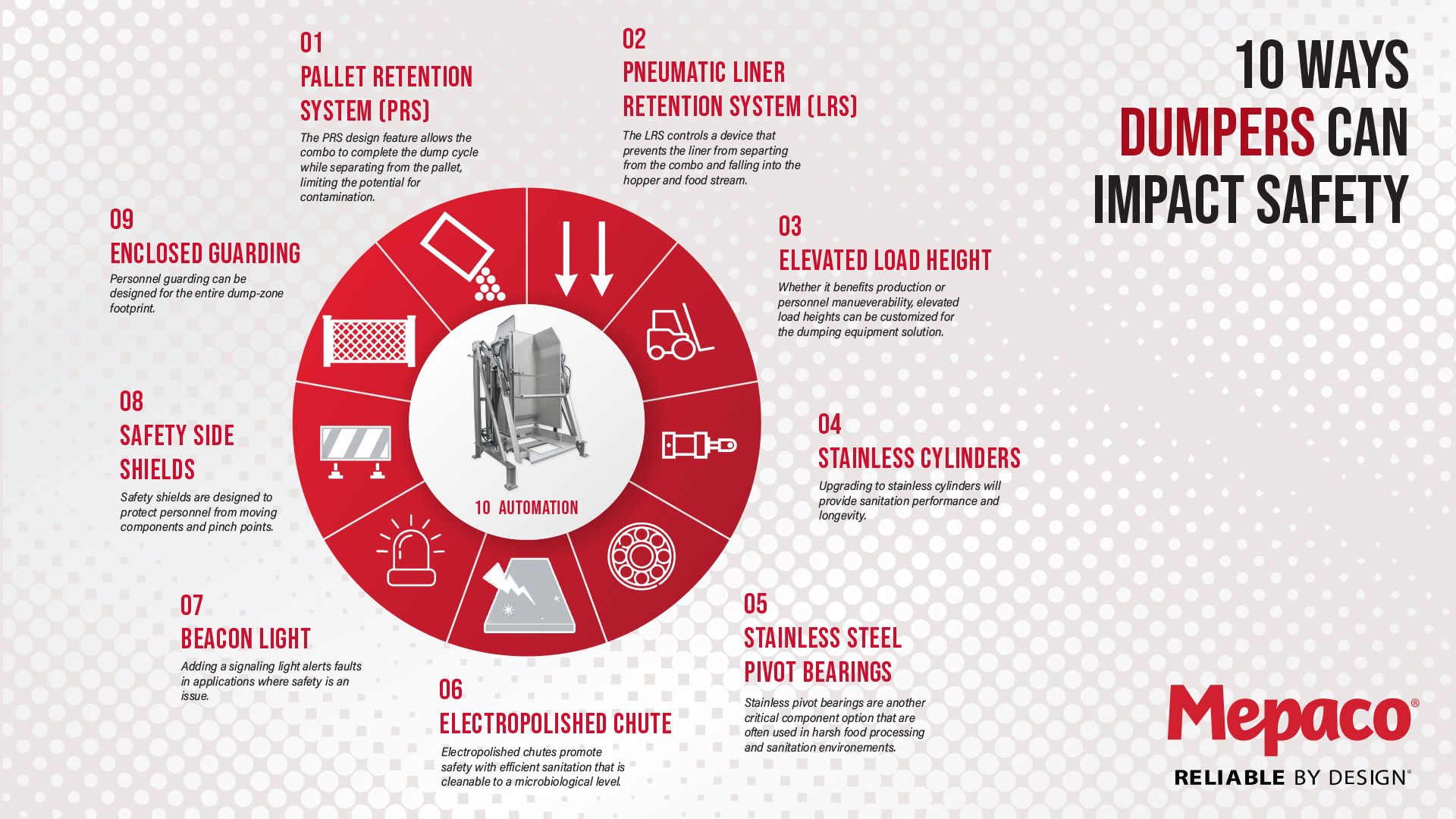

Mepaco offers equipment products that are engineered specifically for the application required for processing, material handling, or an integrated system. Due to the food safety and personnel safety goals across food processors, Mepaco has innovated options to solve these goals. Here are 10 modifications to Dumper designs that can impact safety goals starting at the beginning of the processing line.

1. PRS (Pallet Retention System)

The PRS design feature allows the combo to complete the dump cycle while separating from the pallet, limiting the potential for contamination in the food stream. Upon completion of the dump cycle, the dumper and frame are reunited, and the carriage assembly returns to the start-load position.

2. LRS (Pneumatic Liner Retention System)

The LRS controls a device that prevents the liner from separating from the combo and falling into the hopper and food stream. The liner hold-down prevents operators from having to reach and try to control the liner by hand.

3. Elevated Load Height

Whether it benefits production or personnel maneuverability, elevated load heights can be customized into the dumping equipment solution.

4. Stainless Cylinders

Upgrading cylinders to stainless will provide sanitation performance and longevity.

5. Stainless Steel pivot bearings

Stainless pivot bearings are another critical component option often used in harsh food processing and sanitation environments.

6. Electropolished Chute

Another option is an electropolished chute that promote food safety with efficient sanitation that is cleanable to a microbiological level.

7. Beacon Light

Adding a signaling light alerts faults in applications where safety is an issue.

8. Safety Side Shields

Safety shields are designed to protect personnel from moving components and pinch points.

9. Enclosed Guarding

Personnel guarding can also be designed for the entire dump-zone footprint, optional pocket door designs allow for safe fork truck access for loading and unloading.

10. Automation & Controls

The load set point, detraction, and down control can be integrated into the HMI (Human Machine Interface) with a full safety enclosure and controlled dumper system. The dump function can also be automatically timed to feed downstream equipment using loss-in-weight or level sensor technology. The safety enclosure can also be designed and controlled to open automatically for loading and pallet removal.

Mepaco offers dumpers with a range of versatility from 48” to 175” dump heights. We also manufacture accessories including lifts, vats, tubs, and buggies for your material handling needs. The tote dumpers (DP3000, HD3000 and LD3000) have a working capacity of 3,000 lbs. (1,361 Kg) and a 45-degree dump angle.

Visit Mepaco’s Dumping Equipment for more information or download the infographic now.