Problem

A Pet Food Processor needed to increase throughput due to production delays in waiting for grinders feeding directly to blenders.

Solution

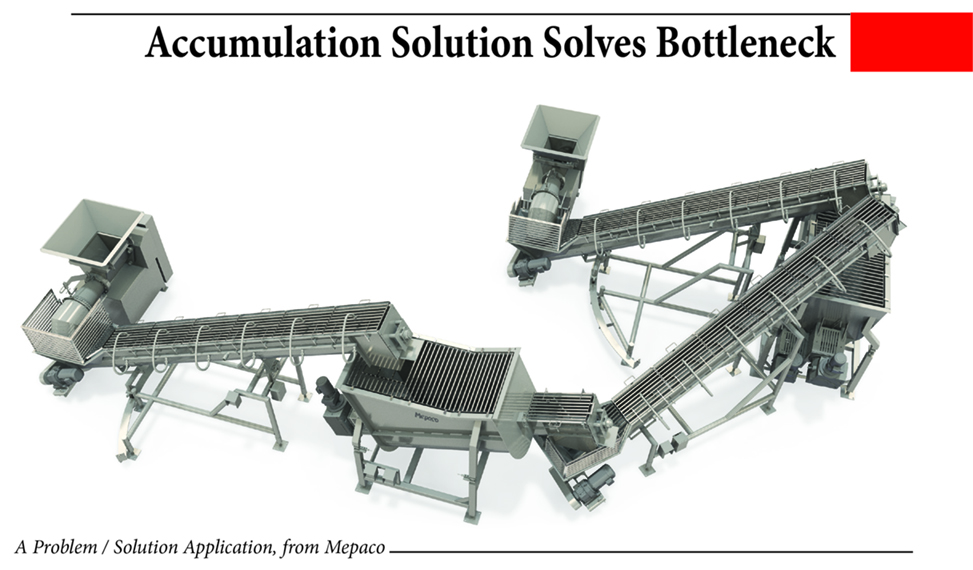

Mepaco engineered a solution that placed surge loaders between the grinder and the blender, allowing the processor to accumulate and stage a full batch of products to be fed into the blender. This system allows the processor to select different volumes of products from a fresh grinder and a frozen block grinder, and feed them together into the surge loader. As soon as the downstream blender is empty, the surge loader quickly refills the blender to begin the next batch.

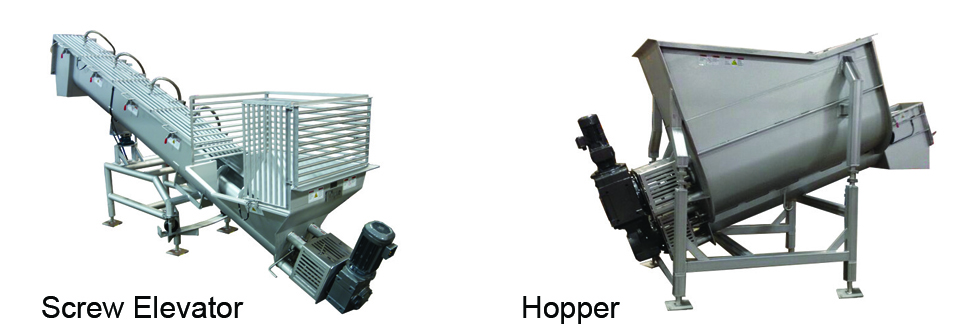

An integral piece of equipment is the Screw Elevator. This equipment was designed with CIP (clean-in-place) spray ball. It features a fixed based with an elevated pivot track to reduce sanitation time.

Another vital piece of equipment are the specialty loaders. These hoppers were designed with extended side walls for high capacity loading.

Product staging and storage was a key factor in getting the maximum throughput from this grind/blend system. This solution saves valuable minutes off each batch that would be spent waiting if the grinders were to directly feed a blender.

Mepaco, part of Apache Stainless, is known for grinding and blending systems. Equipment products, which are customized for the application, include thermal processing solutions, mixers, blenders, cookers, augers, dumpers, sanitary conveyors and material handling systems.