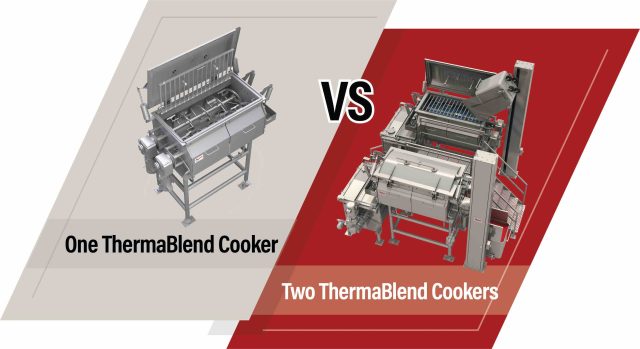

Mepaco engineers cooking equipment for specific production and processing applications. While some food processing customers know the size, type, and required performance of the cooker equipment, other customers come to Mepaco for directional discussions comparing cooker production scenarios and system capabilities. Considerations for choosing one (1) cooker or (2) two cookers for your application, depend on downstream processes, footprint, SKU / production flexibility, and cycling processes.

Downstream Processes

Continuous production processes are usually engineered as two cooker systems. In most scenarios, one cooker is in process while the other cooker is discharging and continually feeding downstream processes.

Adding a holding/buffering vessel to a one-cooker system can improve continuous production in a one cooker system. By adding buffering, the single cooker can discharge into the holding/buffering vessel and begin another cooking cycle. The holding/buffering vessel will temporarily hold product until downstream readiness.

Some processors have manual transfers to downstream processes and produce their product batch-by-batch in one cooker.

Footprint

Cookers that are planned for existing process rooms often result in space restrictions. A single cooker with manual unloading may have more flexibility regarding where the equipment is placed. A processor may benefit from a single cooker with a buffering/holding vessel as long as it is possible to stack the equipment or allow linear space for additional equipment.

Typically, a dual cook system requires more footprint. Depending on the application, the process may include two cookers that discharge into one or individual holding vessels. Mepaco has also designed dual cook systems in linear layouts and placed in two separate parts of the processing room.

SKU and Production Flexibility

A one-cooker solution will produce one batch at a time. When a different SKU is required, the cooker will need to be sanitized and changed out for the next SKU recipe. A two cooker-system can be engineered for multi-recipe processing utilizing one or both cookers. A two-cooker system can also support marginal or fractured batches.

Cycling Processes and Automation

The cycling process (including loading, mixing, blending, cooking, and unloading), is another consideration for choosing between a single or dual cooking system. The longer the cycling process, the longer the wait time for downstream equipment, which can be a reason to consider a two-cooker system.

Cook times for direct steam vary, depending on steam pressure, flow rate, and number of injectors designed into the ThermaBlend cooking solution.

Some processors with smaller volumes or specialty products often choose one cooker for their project. A single cooker may also be specified for projects with true batch applications.

Risk for Downtime

Many customers plan for dual cooker strategies based on the risk of downtime. In basic terms, a single cooker with a catastrophic failure results in 100% lost production, and in a dual cook system, one downed cooker still allows 50% of production to continue until the equipment is back online.

Here is a comparison guide for 2 (200-gallon cookers) to 1 (500-gallon cooker).

Start a conversation about your options with Mepaco sales and application experts. Inquire about a test in our R&D ThermaBlend Cooker.