Depending on the application, processes requiring automation often include a Pump Feeder. In limited floor space, a low-profile surge capacity Pump Feeder, that can also be gentle on the product while maintaining metered flow, is vital to the success of any process. Here are some of the application criteria that go into making the correct Pump Feeder selection for your application.

Application criteria for the Pump Feeder include:

Volume

It is best to talk in terms of volume versus mass when determining the hopper capacity needed for the application. In addition, depending on the operation, the hopper may need to have additional volume to ensure that product flow never stops. This is equally important when using load cells to measure (loss-in-weight) how much product has been discharged as you cannot be loading while the unit is scaling.

Pacing equipment upstream

It is important to know where the product is coming from and the volume delivered. For example, if product is being dumped into the hopper, you may consider the volume of the containers being dumped and what the overall demand will be when the pump delivers product to the downstream equipment. Another example might be if a mixer or cooker is discharged into the Pump Feeder. It is important to know what the required volume must ensure there is adequate space available to receive the next batch of product.

Downstream Equipment

The pace of downstream processes, such as filling, forming, or further processing, must also be included in the engineered solution. The distance (H x V) and diameter of the piping are also considered in calculating discharge pressure. The key is to size the pump so that it gently and accurately delivers product to the downstream process at such a rate as to keep up with the production requirements. The Pump Feeder needs to be able to maintain this rate while still having additional capacity for growth or changes in formulation that may occur in the future.

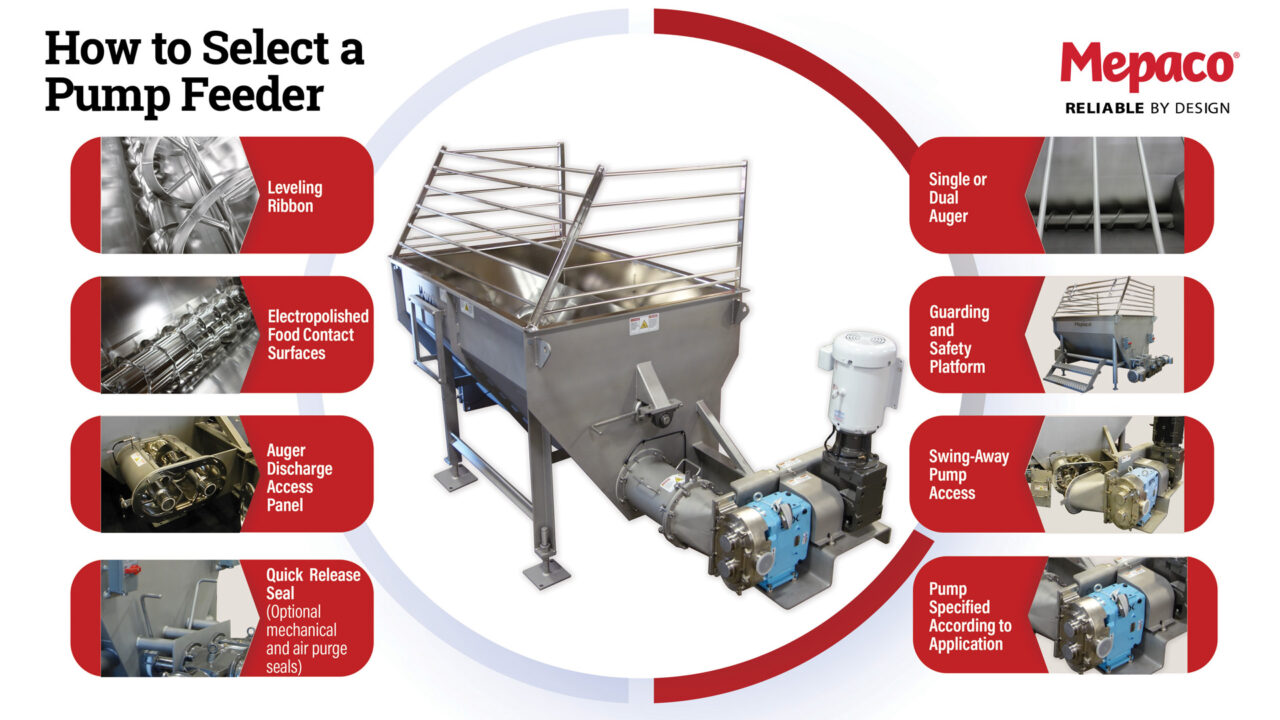

Auger Design

Product density, viscosity, and system speed requirements are considered in specifying a single or dual auger configuration and what pitch may be best. Cold, dense products may have the tendency to bridge which may cause a disruption in flow or cavitation; so, understanding the product behavior is important for selecting the features needed to produce the desired results.

Surge Controls

To avoid overflow situations or stoppage in flow, it is recommended the Pump Feeder use a laser level sensor or load cells to ensure that product flows through the system seamlessly while communicating with the system controls.

Pump

While there are many options for pumps that exist, not all are best suited for every application. Understanding the product characteristics, discharge pressures being developed, customer expectations on product flow and consistency are key to making the correct selection. In addition, pumps that are set up for COP (clean-out-of- place) or CIP (clean-in-place) can play a role in what pumps can be considered.

The key to pumping products with Pump Feeders is to ensure the pump always remains primed. Often these applications are not traditional pumping applications, so it is best to consider going with a larger pump running a bit slower for the best pump performance.

Start-Up

Since the Pump Feeder is feeding a pump, the discharge pump speed is set for the desired flow rate and then the speed of the screws and leveling ribbon are adjusted for a balanced feed to the pump. Once this is in balance, the pump will not be cavitating and the effects of pulsation or recycling will no longer be noticeable. Product will discharge in a smooth, continuous flow.

Pump Feeders are essential equipment in best practice applications in a highly automated, controlled integrated system. In some applications, however, the product or system solution may require a different solution, such as a metering screw conveyor or belt conveyor.

For more information on Pump Feeders, visit our web page or contact our sales and application specialists to discuss your application.