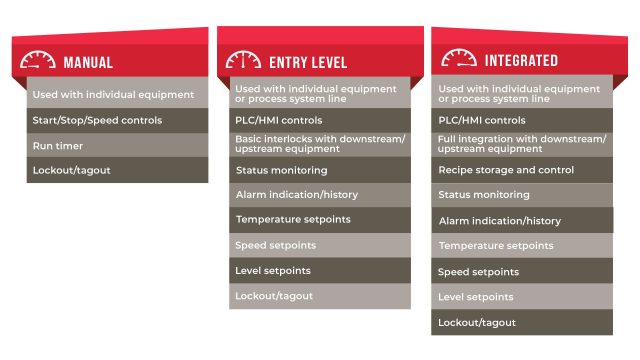

Processors upgrading production and processing equipment have a significant investment including machines, shipping, installation, and commissioning. To consider an upgrade of controls may also mean a change of procedures and processes. Food manufacturers must weigh their concerns, such as payback, capex budget, downtime, and life cycle costs. Mepaco® has helped customers with manual, entry-level, and advanced controls options. Here are some examples of the rationale why customers choose a which level of controls strategy.

Payback

The payback for a controls solution depends on the application. Artisan food processors with less production volume may be well-suited for manual controls. Another example of a simple controls package investment could also be testing equipment, R&D equipment, or perhaps short run product lines.

In food processing lines with automation as the driving strategy, many processors utilize higher-end controls with computerized recipes and automated controls of integrated equipment to meet goals and return on investment.

Capex Budget

Financial reservations are a top concern for all sizes of companies to consider in an equipment or system investment. The pros and cons should be carefully considered on the system solution and the equipment and controls partner.

Increased production goals drive food processors to invest in automation to sustain growth and competitiveness, with other factors including food safety, personnel safety, and labor utility costs.

Downtime

In some examples, a capital commitment to a new system with advanced controls are a solution to reduce loss of downtime, specifically downtime related to manual processes such as loading and unloading.

Some processors struggle with effective loading times when using non-integrated, manually intensive equipment. New equipment solutions with an integrated recipe and process control package can be engineered to solve automation goals and reduce or redirect labor.

Life Cycle

Life cycle of equipment is affected by environment, proper use, and hours of operation. Stainless equipment, however, generally lasts a long time. Mepaco® has Mixers that are still in operation after 40 years.

From a controls package standpoint, advanced controls packages can be changed and upgraded unless it is a legacy system, which would require a full processor and software upgrade.

In a round table discussion of Mepaco® application specialists, engineers, sales and service technicians, the team offered up trends and considerations from component level options to entire system solutions that help solve automation and reduce labor in food manufacturing processes. For more information, read our e-book “Processing Automation Trends”.