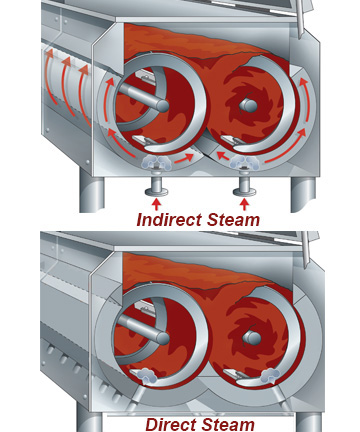

The above illustration shows the direct and indirect steam capabilities that exist with both the single and double agitated ThermaBlend™ batch cookers.

In the process of indirect steam heating, steam is injected into the ASME thermal outer jacket and heats the product through conduction. Since there is no added moisture to the product, the potential exists for product burn-on. Both the single agitated and double agitated ThermaBlend™ cookers feature Mepaco’s spring-loaded scraper system. By eliminating burned on product, the patented scraper system allows maximum heat transfer and allows for more effective sanitation. Applications for indirect steam heating include: stews, sauteed vegetables, scrambled eggs, granola, ground beef and other types of food products where additional moisture is not desired. The indirect steam cooking option can also provide caramelization if required for the application.

Thermablend™ cookers also have a direct steam option. When additional moisture is required for the product, steam is modulated and added to the food product. Advantages of direct steam cooking include reduced batch cooking times and reduced burn-on. Application examples include: moist pet food, thick sauces and soups. Direct steam is often used when the product is more viscous or has heavy particulates.

Direct, indirect or both steam heating techniques can be used in Thermablend™ cookers. Utilizing both indirect and direct steam options will substantially increase batch cycle cooking efficiencies. Viscosity and make-up of food product, processing and production requirements dictate which type of Thermablend™ and agitator option is best utilized for the application.

Follow this blog for upcoming articles on Thermal Screws, and other thermal processing solutions from Mepaco.