Vacuum

Stuffer

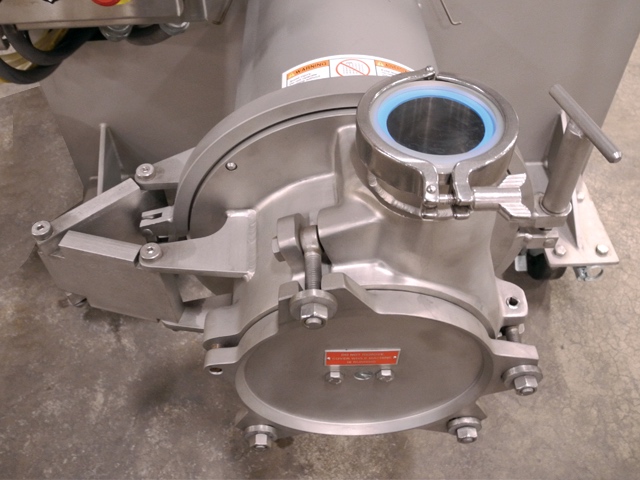

Mepaco’s Continuous Vacuum Stuffer removes entrapped air from both fine and coarse ground products. As a result, the 420V Vacuum Stuffer produces a firmer, denser product. Through consistency and uniformity; slicing yields are improved while color, temperature and texture are maintained.

The continuous vacuum operation eliminates the need for batch vacuuming which improves plant efficiencies and reduces the risk of product contamination.

Model 420V Vacuum Stuffer Specifications:

- Heavy-Duty T304 S.S. Construction

- USDA/FDA Approved

- Left or Right Handed Units

- Load Sensing Hydraulic Drive System

- Paddle Agitation

- Vane-Type S.S. Product Feed Pump W/3″ Discharge

- Tachometer Readout

- 5 HP Vacuum Pump W/Clear View Filter

- Nominal Capacity: 11K Lbs/Hr (5,000 Kg/Hr)

- Maximum Capacity: 36K lbs/Hr (11,000 Kg/Hr)

- Discharge Pressure: 150 PSI (10 Bar)

- Hopper Capacity: 24 Ft3 (680 L)

- Air Required: 2 Ft3 @ 100 PSI (7 Bar)

- Hydraulic Power: 20 HP (15 kW) TEFC W/NEMA 4 Enclosure

- Electrical: 230/460V, 3 Phase, 60 Hz

NOTE: Capabilities are general estimates and may change depending on the specific application.

Related Posts

FAQ – VACUUM STUFFER

What is the throughput of a vacuum stuffer?

What types of food manufacturing applications utilize a vacuum stuffer?

How deep of a vacuum can you pull?

Does the vacuum stuffer improve shelf life?

Is the vacuum adjustable?

Do you have variable hydraulic options?

How does the equipment determine level of product in the tub?

Is the feed pressure adjustable?

Can it be hooked up to an emulsifier or an inline grinder?

Is a vacuum included?

Does this unit include a hydraulic pump?

Is an electric model available?

Does the stuffer run batches or is it designed for continuous operation?

Why is my probe not working?

Why is my pump not working at full capacity?

Why does my unit not maintain vacuum?

What is the size of the tubing inlet?

Can a stuffer be filled?

Should an emulsifier be placed before or after the stuffer?

How do you check to see if all air voids are out of the product?