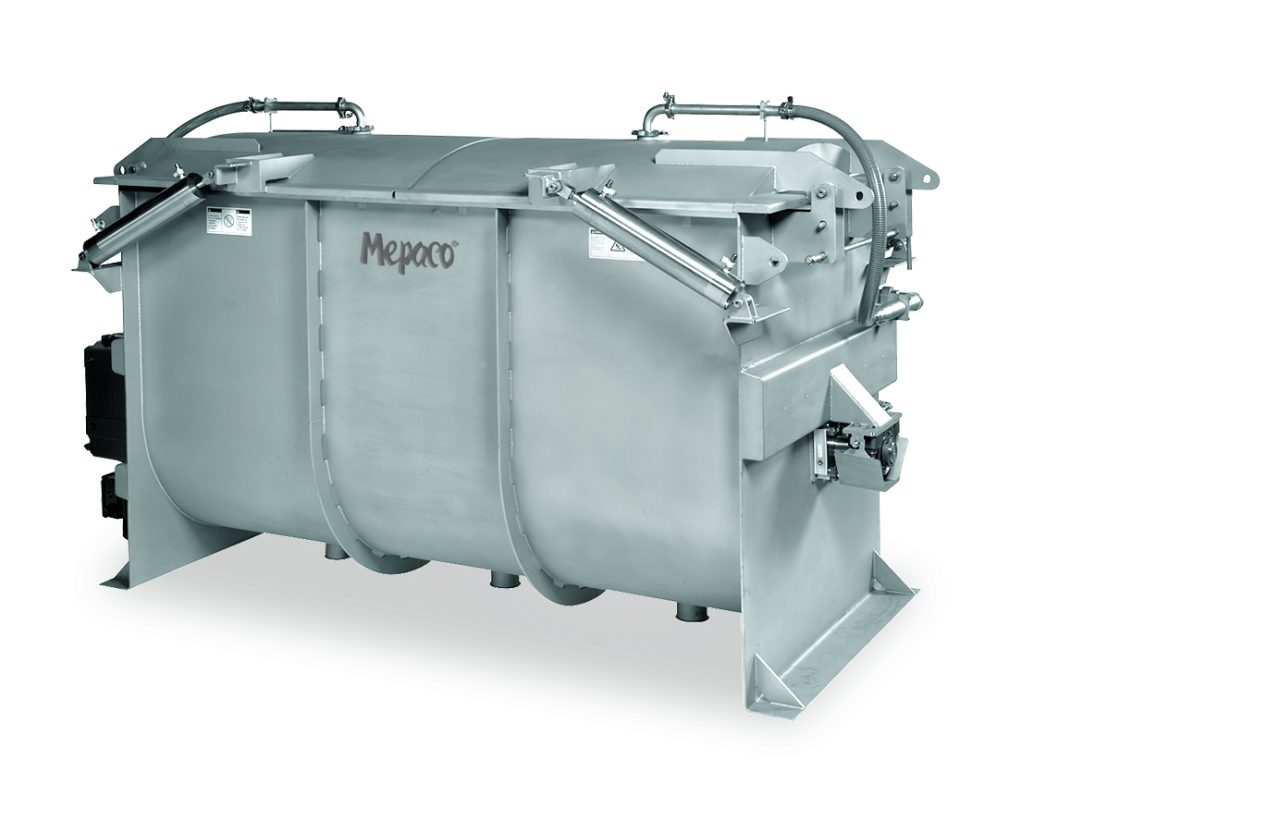

Industrial

Mixer-Blender

The Mixer-Blender Series is designed for versatility to meet a range of application challenges. Our application expertise will drive quick, accurate homogeneous blends with reduced cycle times to maximize productivity goals.

- Heavy-Duty 304 or 316 S.S. Construction

- USDA/FDA Approved

- Capacities: 50-Pounds to 15,000-Pound Units

- Agitation Options: Paddle, Overlapping Paddle, Ribbon, Solid Flight

- Discharge Options: End Discharge, Bottom Discharge, Full-End Discharge, P.D. Pump

- Finish Options: Bead-Blast, Passivated, 2B, #4 or Electropolishing

- Flange Mounted Drives

- Vacuum or Non-Vacuum Operation

- Temperature Control Options: ASME Dimple Jacketing, Steam Injection, CO2 Injection

Our Mixer-Blenders can be equipped as a Mixer-Grinder. With superior blending paired with a precision grinder, the Mixer-Blender can be adapted for small and large production demands.

Product Temperature Control

Code-stamped, ASME rated, high-pressure dimple or stay-bolt jackets (including heat shields) are available with direct or indirect steam options. Cooling jackets, insulation/cladding, or injection systems (CO2 or N2) are also available with applicable solenoid controls, manifolds, injectors, and exhaust covers.

Vacuum Sampling Systems

The optional sampling system quickly and systematically retrieves random samples from the product blend providing a safe and sanitary method for sampling.

Related Posts

FAQ – Industrial Mixer-Blender

The recommended level is from the center of the shaft to the tips of the agitator. Any level less or greater would have a negative impact on blending efficiencies and effectiveness.

The mass is determined by product density. We use an estimated density of 50 lbs/ft3 for batch size formulations. For example, a 100 ft3 until will produce a 5000 lb batch. Using this example, if the goal is to produce a 5000 lb batch using a product that is 45 lbs/ft3, we would recommend a 120 ft3 unit that would have a 5400 lb capacity.

Yes, we can also provide a frame design from angle.

Our covers can be set up to slide or hinge (side/end hinge).

Mepaco offers a vacuum sampling mechanism that bring the sample to a container without the need for interrupting the batch process.

On a scale from gentle to aggressive, ribbon agitators are the most gentle on products, followed by paddles and then overlapping paddles. Mepaco’s design and engineering team will work out a solution that considers the product, cycle times and process requirements.

Check all seals and gaskets. Check that the splice interface on the gasket is at a 45-degree angle and is overlapping. Examine wear on the shaft, valves, vent valve on cover, any ingredient connections and be sure clamps are tight with gaskets in place. Then pull vacuum. The needle should reach approximately 27-29 Hg and not lose more than 2 Hg in five minutes.

CO2 cooling options include liquid and a liquid/vapor combination. When using liquid CO2, we inject via individual valves for each port. If a liquid / vapor option is used, we include independent valves for liquid and vapor. Note: N2 is another cryogen option available as an alternative to CO2.

Bottom CO2 systems are more efficient than snow horns because less CO2 snow is lost is lost through the CO2 exhaust system. Bottom CO2 injectors are installed so that the product stops the velocity of the injected snow so it is less likely to become entrained in the exhaust air system.

Mixer-Cookers can be designed to heat or cool product through the use of direction injection and / or indirect jacketing.

Mepaco’s mixer can be designed for compliance with 3A, WDA and other sanitary or safety regulatory specifications. Official certifications are available upon request.

Refer to the chart for weight and volume specifications. This chart is also available on the Brochure tab above.