The Pet food processing industry has witnessed significant growth in the last few years, according to FPSA, Pet Food Processing Equipment Market Forecast to 2026. The study states that the growth is due to an increase in pet ownership and adoption rate and a rise in urbanization across developing countries. The changing consumer trends such as demand for nutritious alternatives and high-quality pet food and proteins have further led to changes in the pet food equipment industry.

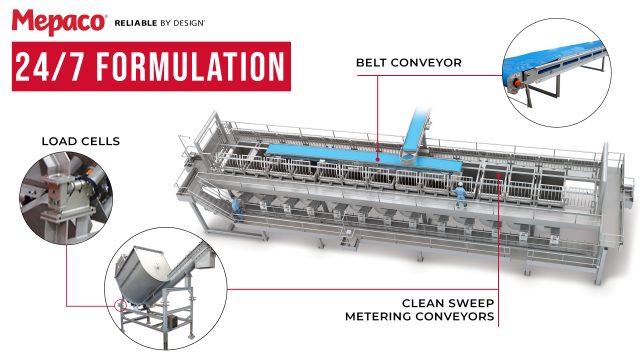

Market trends and overall growth have led Mepaco to engineer more systems for pet food manufacturers. This blog highlights a bin formulation system that Mepaco has manufactured for numerous pet food processors. The bin system utilizes on-demand controls to provide around-the-clock formulation. The core equipment in this system are the Clean-Sweep Metering Conveyor, Belt Conveyors, and Load Cells.

CLEAN-SWEEP METERING SCREW CONVEYORS with SURGE LOADING CAPABILITIES

Clean Sweep Metering Screws provide the surge loading benefits required to fulfill production goals in the batch formulation system. The equipment is custom designed as part of a lineup in a bin configuration. Each hopper supplies different ingredients for the (mass scale) pet food production line.

Ruggedly built for continuous operation, the Clean-Sweep hopper design offers an off-set agitator that clears product from the hopper between batches.

LOAD CELLS

LIW (loss in weight) Load cells are used to measure product displacement over a given time. LIW Load Cells provide a highly accurate way to utilize metering screw conveyors and provide processing efficiencies since all ingredients are delivered simultaneously.

Downstream equipment such as mixers, blenders, or cookers signal the raw material in a given SKU. The screw conveyors deliver the correct quantity of product required through the primary grinder and then to the batching bins for final formulation.

Belt conveyors deliver ingredients on-demand to the exact bin position with versatility and deliver formulated products to downstream operations.

This processing line reduced labor and eliminated downtime with continuous, around-the-clock large batch production: utilizing real-time material availability and on-demand formulation.